FS62WSS–可焊接应变传感器-德国HBM

FS62WSS–可焊接应变传感器

很容易地点焊到金属结构上,安装后可立即进行测量

编织电缆, 耐高温 (-40ºC[-40ºF] 到 100ºC[212ºF]) 极高应变 (±10000µm/m) ,适合实验室应用

室外应用可使用 Ø3mm 芳纶或铠装电缆

更宽应变测量范围能满足最现代钢应变测量要求,最高可达 ±5000μm/m

关于温度补偿,推荐使用温度传感器 FS63WTS

HBM 推荐使用 Heller 电焊机或类似设备,采用 ABM75 或 AK22 保护层获得更长服务寿命

Special features

Spot welding installation

Robust design

Configurable wavelengths, cable lengths and connector types

Description

The Weldable Strain Sensor is a Fiber Bragg Grating (FBG) based sensor designed to be easily spot welded to metallic surfaces using a low power welding machine. Prepared with a robust and resistant layout, this sensor on its rugged version can be used in demanding environments as seen in many field applications.

The FS62WSS is based on the newLight® technology developed by HBM FiberSensing to combine particular advantages of the FBG overcoming technical compromises that existed so far. newLight® sensors employ high strength fiber coatings and different FBG fabrication techniques to ensure increased strain measurement ranges, enhanced fatigue resistance and higher measurement accuracy. The low bend loss, telecom compatible fiber opens the possibilities for innovative sensor designs as well as the straightforward usage of multiplexed sensors on the same fiber even if kilometers apart. The technology is completely passive, self-referenced and compatible with most interrogators.

Combine this with other strain and temperature sensors from HBM FiberSensing with corresponding cable types using the configurators K-FS76ARD and K-FS76ARM.

Benefits and applications

Possible measurement right after installation

Configuration available for different strain measurement and operating temperature ranges

Suited for harsh environments such as structural health monitoring of large structures in civil engineering, pipelines, ship hulls and offshore application

Fiber Bragg grating technology

Absolute reference measurement

Insensitive to EM/RF interferences

Passive (can be used in Ex-areas)

Intrinsic multiplexing capability reducing cabling requirements

Long distances between sensors and the interrogators possible

Combinable with other sensor measurands

| Sensor | ||||||

| k-factor (sensitivity)1) | n.a. [pm/(μm/m)] | 0.76±0.03 ([1.2]) | ||||

| Resolution2) | μm/m | 0.5 | ||||

| Measurement range | μm/m [%] | ±5000 [0.5] | ||||

| Gauge length | mm | 40 | ||||

| Operation and storage temperature | °C | -20 … +803) | ||||

| Operation4) and storage humidity | % | ≤100, < 95 | ||||

| Temperature cross sensitivity5) | (μm/m)/°C | 6.6±1 | ||||

| Sensor bend radius6) | mm | >400 | ||||

| Attachment method | n.a. | Spot weld7) | ||||

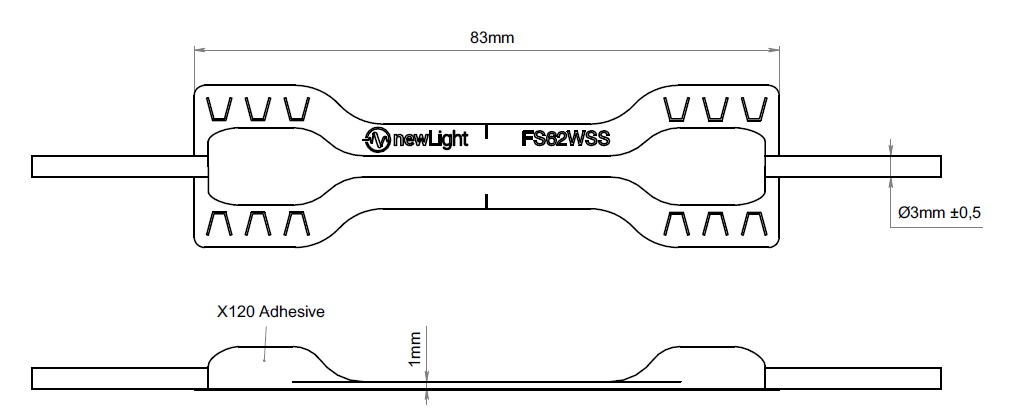

| Dimensions8) | mm | 83±0.5 x 23±0.5 x 6±0.5 | ||||

| Weight9) | g | Ø 3 mm aramid: 19; Ø 3 mm armor: 63 | ||||

| Main materials | n.a. | Stainless steel, silicone, X120, ormocer® | ||||

| Bragg wavelengths | nm | 1500 … 1600 (±0.5) | ||||

| Fiber core, cladding and coating diameter | μm | 8/125/195 | ||||

| FWHM, reflectivity and side lobe suppression | n.a. | > 0.2nm, 20±6%, > 7dB | ||||

| Inputs / Outputs | ||||||

| Cable type | n.a. | Ø 3 mm aramid (Hytrel, Kevlar® and PE) or Ø 3 mm armor (Hytrel, stainless steel spiral, Kevlar®, stainless steel mesh and PE) | ||||

| Cable bend radius | mm | > 5 | ||||

| Cable length10) | m | 0 … 20±0.05 | ||||

| Connectors | n.a. | FC/APC, SC/APC or NC (No Connectors) | ||||

| Options | ||||

| 1 | ARD - Aramid cable; ARM - Armor cable | |||

| 2 | NC - No connector; FC - FC/APC; SC - SC/APC | |||

| 3 | 0.5 m < Cable length < 20m @0.5m steps | |||

| 4 | 1510nm ≤ Wavelength12) ≤ 1590nm @10nm steps | |||

| 5 | 0.5m < Cable Length < 20m @0.5m steps | |||

| 6 | NC - No connector; FC - FC/APC; SC - SC/APC | |||

Standard item

1-FS62WSS-ARM/1510

1-FS62WSS-ARM/1520

1-FS62WSS-ARM/1530

1-FS62WSS-ARM/1540

1-FS62WSS-ARM/1550

1-FS62WSS-ARM/1560

1-FS62WSS-ARM/1570

1-FS62WSS-ARM/1580

1-FS62WSS-ARM/1590

文章版权备注

- 2019-07-12FS62RSS坚固型应变传感器-德国HBM

- 2019-07-11FS62PSS贴片应变传感器-德国HBM

- 2019-07-09FS62CSS复合应变传感器-德国HBM

- 2019-05-08FS70多布拉格光栅-德国HBM

- 2019-04-24FS63光纤温度传感器用于精确温度测量-德国HBM

- 2019-04-19newLight系列:FS62光纤应变传感器 德国HBM

售前咨询

售前咨询