CERAM-计量/混合/提取/定量给料系统

客户

CERAM是法国的一家专业从事物料计量,混合,提取和转移的自动化应用。CERAM凭借其在农业食品,化学品和制药行业的粉末和颗粒剂量方面的专业知识建立了良好的声誉。

它的要求

对于其客户,一个糖果制造商,CERAM必须设计一个供给挤出机的系统。

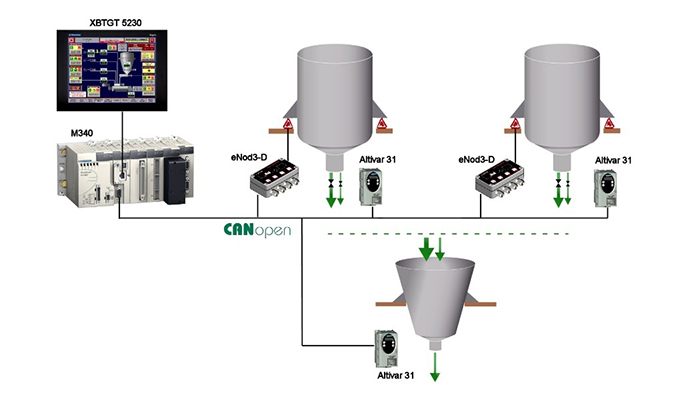

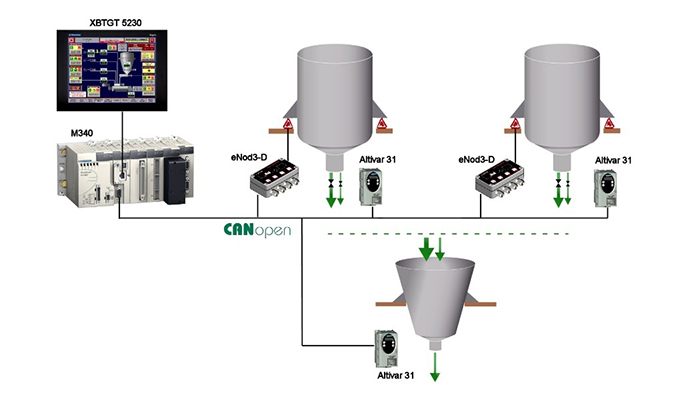

该系统基于两个粉末储罐,每个储罐配有用于定量给料的称重传感器。第三个罐用于在给药后混合两种产品。混合物通过连续方法进料挤出机。

我们的方案

SCAIME与施耐德电气合作提供解决方案。这种合作在施耐德电气的PLC和SCAIME的称重电子设备之间提供了完美的互连。

SCAIME产品

六个F60X称重传感器,带有用于储罐的安装套件

两个eNod3-D配料控制器

自动化产品

- 一台施耐德电气M340 PLC

- 一台施耐德电气XBTGT 5230 MMI

- 三个Altivar 31变速器

在此解决方案中,M340 PLC提供系统的整体控制,而称重操作由eNod3-D配液控制器管理。

每个eNod3-D并行工作,并根据从M340接收的参数完全管理计量周期。

同时,M340控制混合器和挤出机的供应。

客户利益

该架构经过优化,可确保每台设备执行最有效的任务。

CANopen网络提供系统不同元素之间的完美连接。

The customer

CERAM is a French specialist in automated applications for dosing, mixing, extraction and transfer of materials. CERAM has built its reputation on its expertise in dosing powders and granules for the agri-food, chemicals and pharmaceuticals industry.

Its requirement

For its customer, a confectioner, CERAM had to design a system to feed an extruder.

The system is based around two powder storage tanks, each equipped with load cells for dosing. The third tank is intended for mixing the two products after dosing. The mix feeds the extruder by means of a continuous process.

Our solution

SCAIME offered a solution in partnership with Schneider Electric. This collaboration provides perfect interconnectivity between Schneider Electric’s PLCs and SCAIME’s weighing electronics.

SCAIME PRODUCTS

- Six F60X load cells with mounting kits for tanks

- Two eNod3-D dosing controllers

AUTOMATION PRODUCTS

- One Schneider Electric M340 PLC

- One Schneider Electric XBTGT 5230 MMI

- Three Altivar 31 variators

In this solution, the M340 PLC provides overall control of the system while the weighing operations are managed by the eNod3-D dosing controller.

Each eNod3-D works in parallel and fully manages the dosing cycle based on parameters received from the M340.

In parallel, the M340 controls the mixer and the supply to the extruder.

Customer benefit

The architecture is optimised to ensure that each device performs the tasks at which it is most effective.

The CANopen network provides perfect connectivity between the different elements of the system.

文章版权备注

- 2019-09-24农牧养殖自动配料称重系统-自动化养殖控制

- 2019-06-22NCS非连续累计自动秤产品(散料秤)

- 2019-06-22DCS自动定量包装秤产品

- 2019-06-22粉体失重式恒流量给料机

- 2019-06-22粒料失重式恒流量给料机

- 2019-06-22失重秤 采用高精度传感器模块

- 2019-04-12温氏食品集团-养猪场料仓称重

- 2019-04-12UMICORE-化工行业料仓称重

- 2019-04-12SASIL-连续粉末混合定量给料称重系统

- 2019-04-12SPIROFLUX -混合和配料系统

售前咨询

售前咨询